PCBway is known for its quality PCB, what makes their PCB special? PCBway offers many customizations to their PCB, solder mask color is the one that many electronics enthusiasts looking for.

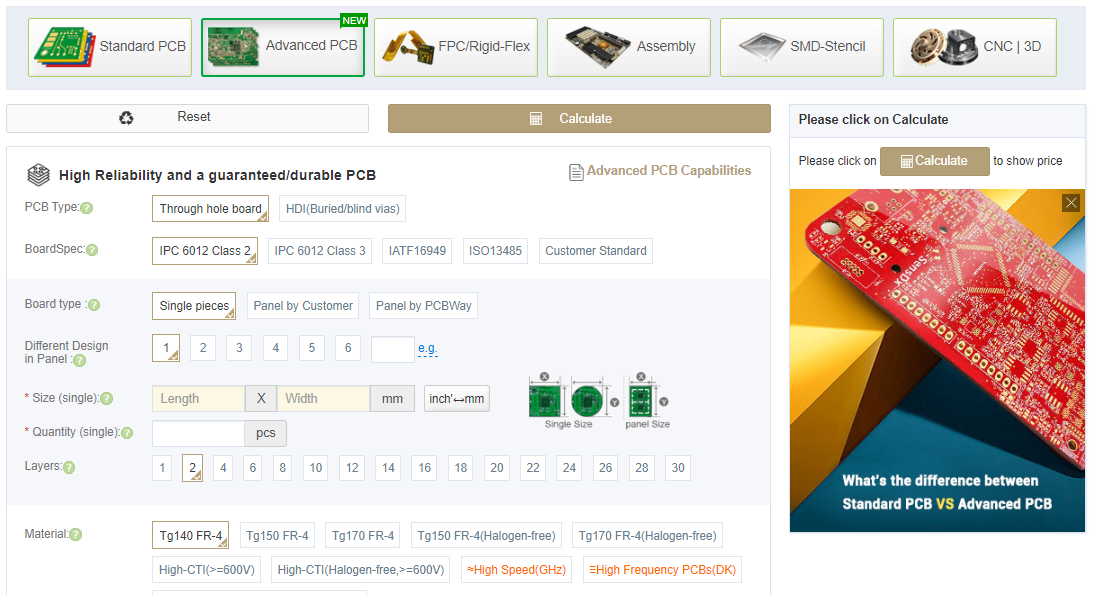

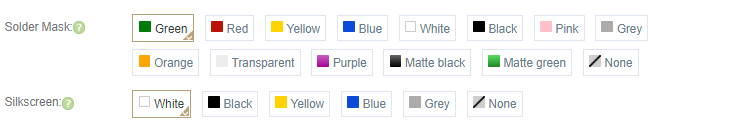

PCBway offers Pink, Orange, Grey, and Transparent solder mask color. These options can be found in Advance PCB as you can see in the image below:

After that material selection for the PCB's manufacturing, PCBways used Epoxy Glass material which is also known as FR4 a code name for Epoxy Glass material, A mixture of flame-retardant epoxy resin and glass fabric is used to create the FR4 class of printed circuit board base materials. FR stands for flame retardant and complies with UL94V-0 standards. FR4 is ideal for common applications since it adheres to copper foil well and absorbs little water.

The next and most important step is TG, TG stands for glass transition temperature which plays important role in PCB manufacturing, A huge need for boards with high Tg has emerged with the advancement of electrical technology. The transition temperature (Tg), which occurs when the base material (polymer or glass) transitions from a solid, hard, and glassy state to a rubbery state, is one of the most crucial characteristics of epoxy. The Tg value of each PCB varies depending on the substrate. If the operational temperature of the PCB surpasses its Tg value, the PCB will also begin to alter its state, which will have a negative impact on PCB construction. Because the substrate offers the board higher heat resistance, and mechanical, and chemical stability at high temperatures, high Tg PCB boards are more stable there.

TG Introduction

Glass transition temperature, or TG, is a mechanical parameter that denotes the temperature at which the base material (glass or polymer) changes from a glassy, solid, rigid condition to a rubbery state. When the Tg is surpassed, materials shift structurally and become stretchy rather than melting. Changes in temperature can significantly affect how well PCBAs function, are reliable and are made. When temperatures rise, materials expand, but the primary materials used to make PCBs have different thermal expansion coefficients. When electrical testing (Open/Short tests) are conducted near the end of manufacturing, this might result in mechanical stress that can lead to micro-cracks that might go unnoticed. In the best situation, these microcracks result in failures that are discovered after brazing. In the worst situation, the completed product can have random failures!

The most often used material for PCB fabrication is copper-coated laminate (FR4) treated with internal layer imaging, however applying PREPREG layers, which become stiff only after lamination, is necessary. To maintain PCB stability, the FR4 Tg must not be exceeded when applying the heat necessary for PREPREG stiffness. The median FR4 Tg is 150 °C, the high Tg is higher than 170 °C, and the standard Tg is between 130 and 140 °C. High Tg FR4 will outperform regular FR4 in the hot state in terms of mechanical and chemical heat and moisture resistance.

The following table shows the High-Tg PCB fabrication capabilities of PCBWay:

| Feature | Capability |

| Material | Tg140 FR-4,Tg150 FR-4,Tg170 FR-4,Tg150 FR-4 (Halogen-free), Tg170 FR-4 (Halogen-free) |

| Min. Track/Spacing | 2mil |

| Min. Hole Size | 0.15mm |

|

Finished Cooper |

0.5-13oz |

| Board Thickness | 0.2-6mm |

| Surface Finishing | HASL lead-free, Immersion gold, OSP, Hard Gold, Immersion Silver, Enepig |

| Solder Mask | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green |

| Silkscreen | White, Black |

| Via Process | Tenting Vias, Plugged Vias, Vias not covered |

| Testing | Fly Probe Testing (Free) and A.O.I. testing |

| Build time | 7-10 days |

| Lead time | 2-3 days |

When selecting your PCBs, one of the important elements to take into account is TG. In order to choose the right material, especially for PCBs subjected to high working temperatures, it is crucial to ascertain the temperature at which the PCBs will be exposed as early in the design process as possible.

Get your PCB Custom Solder Mask Color with PCBway with amazing PCB Quality for your projects